I know a few people have heard about the computer program Linkage, and I thought it'd be cool to see some different ideas that people have come up with. So if you have any homemade designs, post them here! If you're not aware of the program I recommend checking it out. It makes things a lot easier if you're the kind of person that spends a lot of time drawing up different designs that you've thought up during work or class

I'll start it off with one of my recent designs. It's called the jesus... nobody fvcks with the jesus... nvm, bad reference haha. anyways it's called the TBR Gravity. enjoy

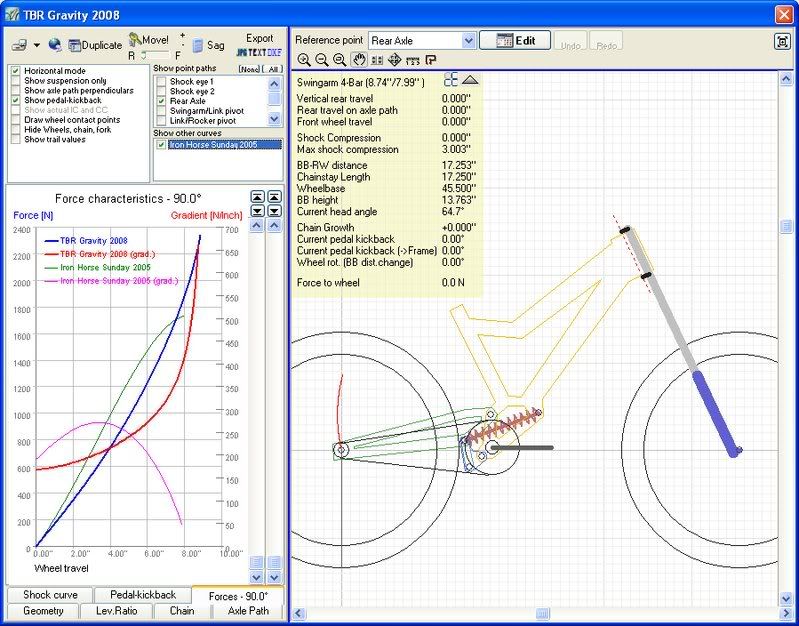

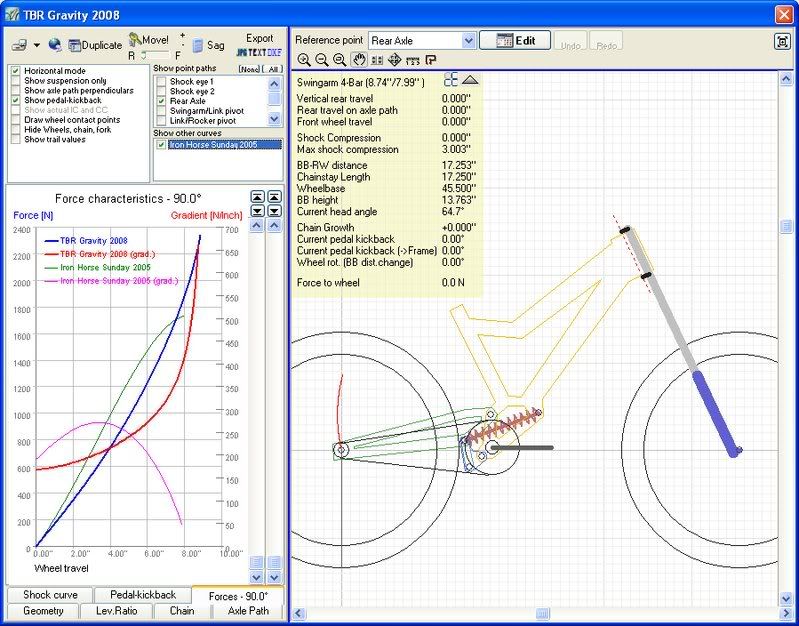

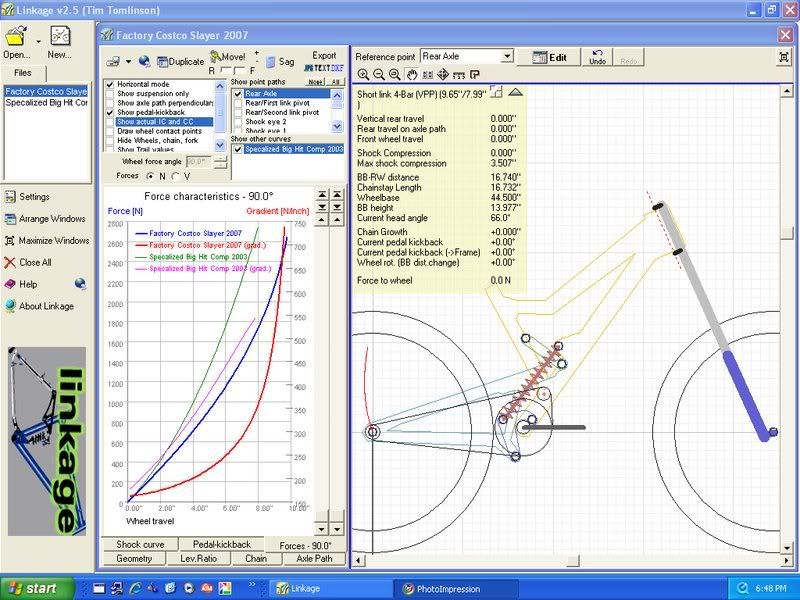

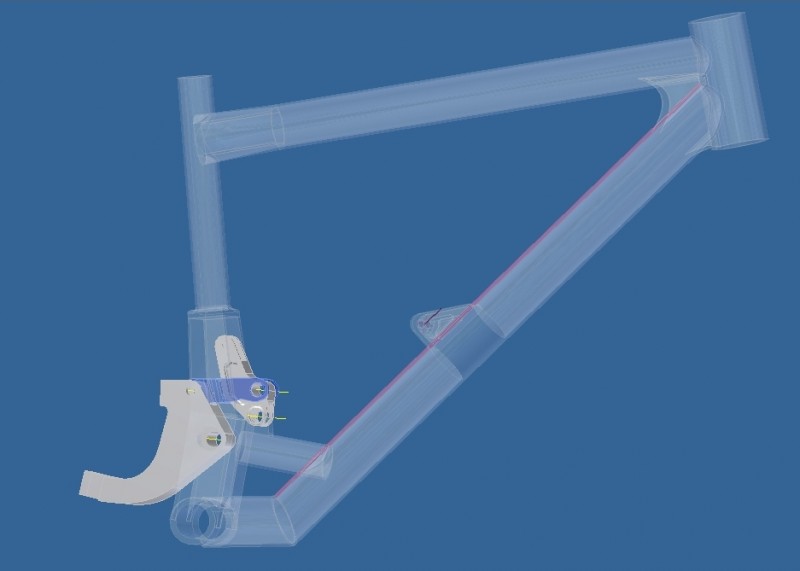

unsagged

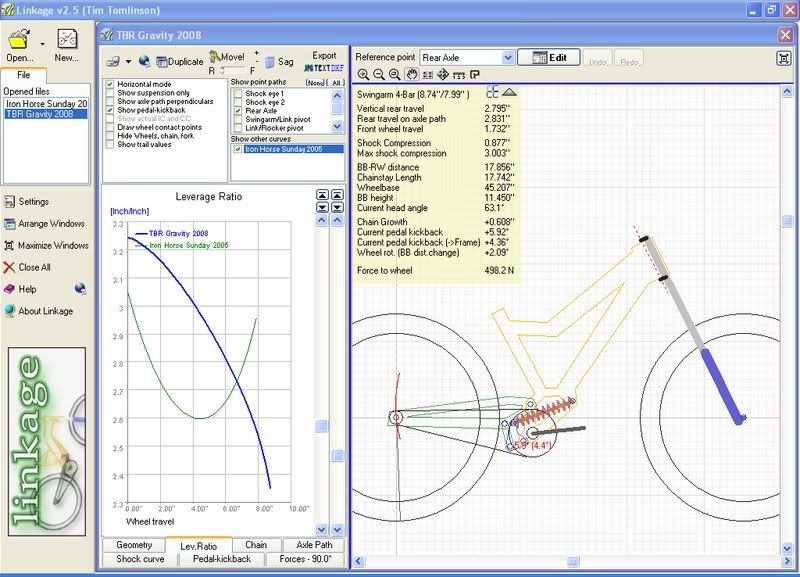

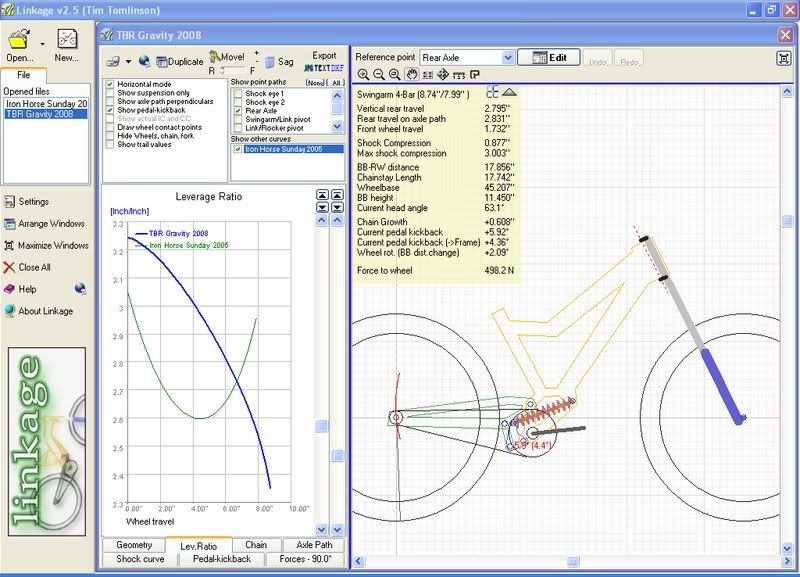

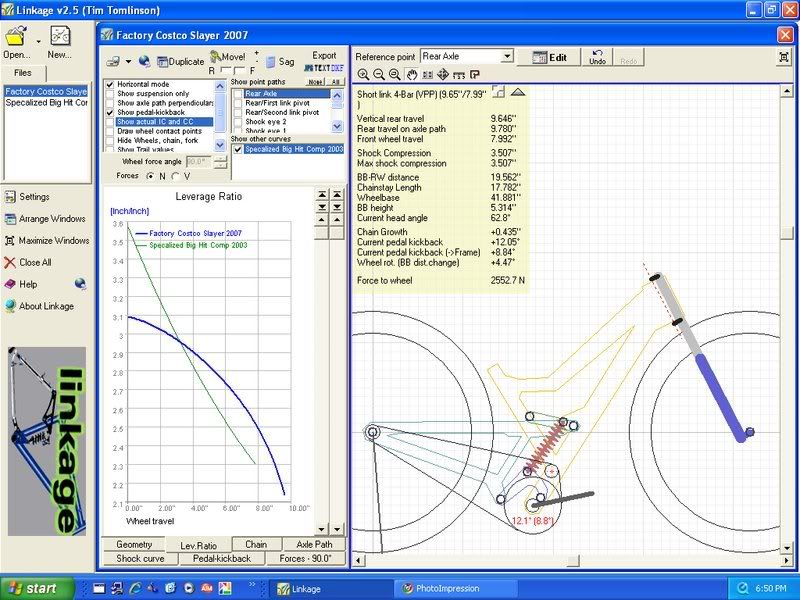

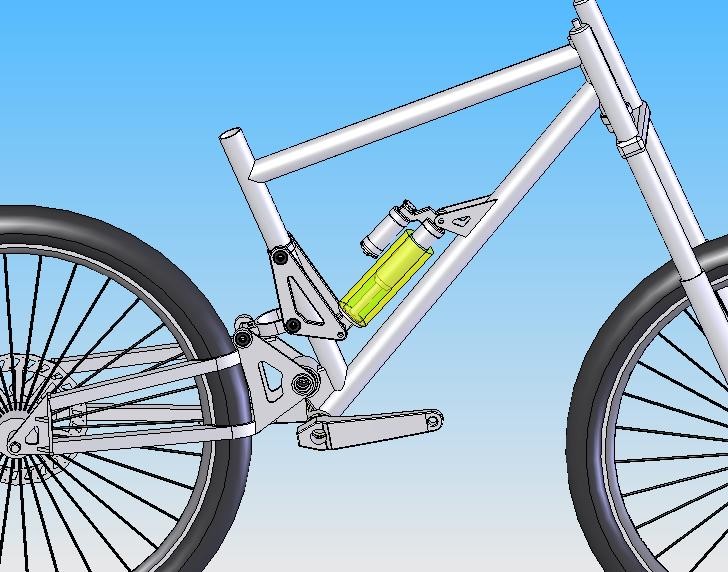

sagged

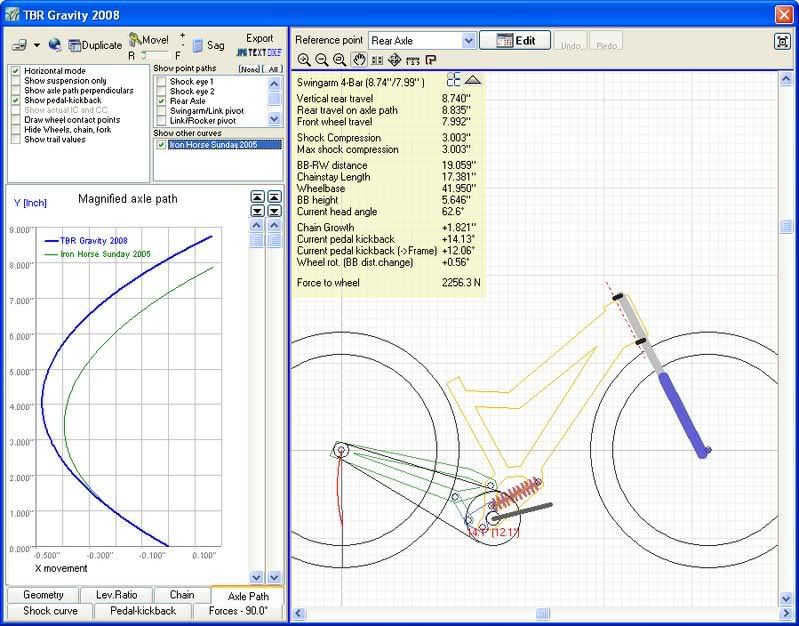

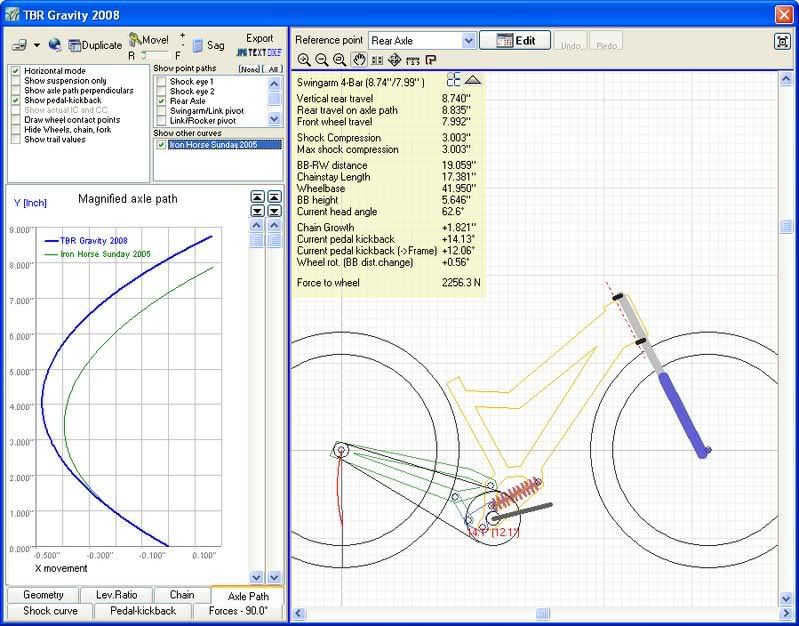

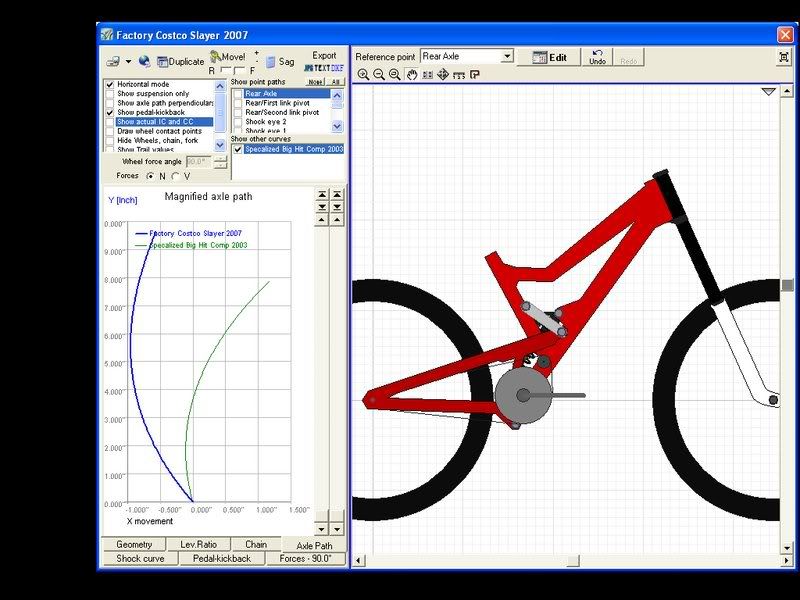

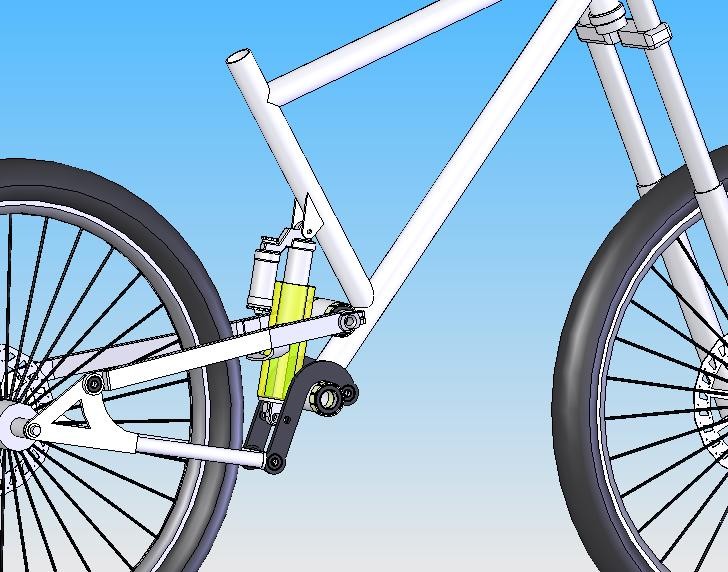

bottomed

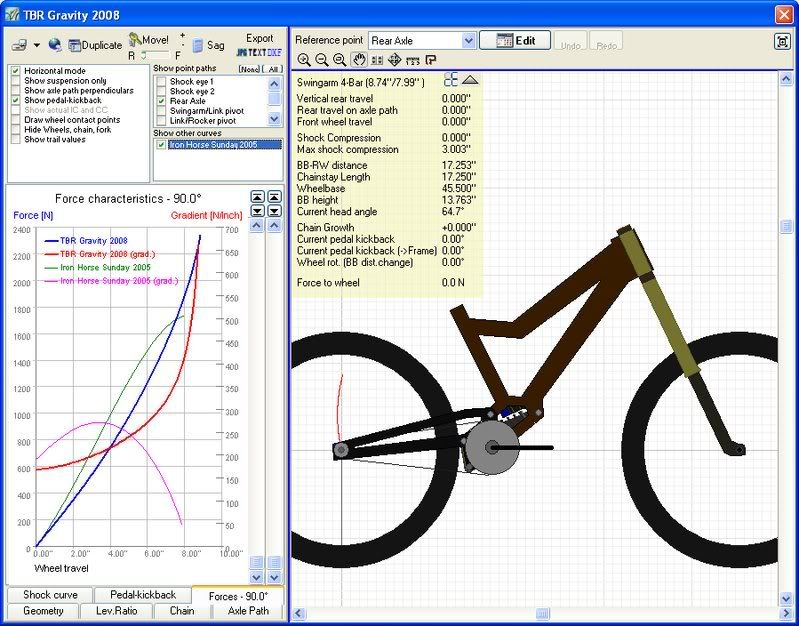

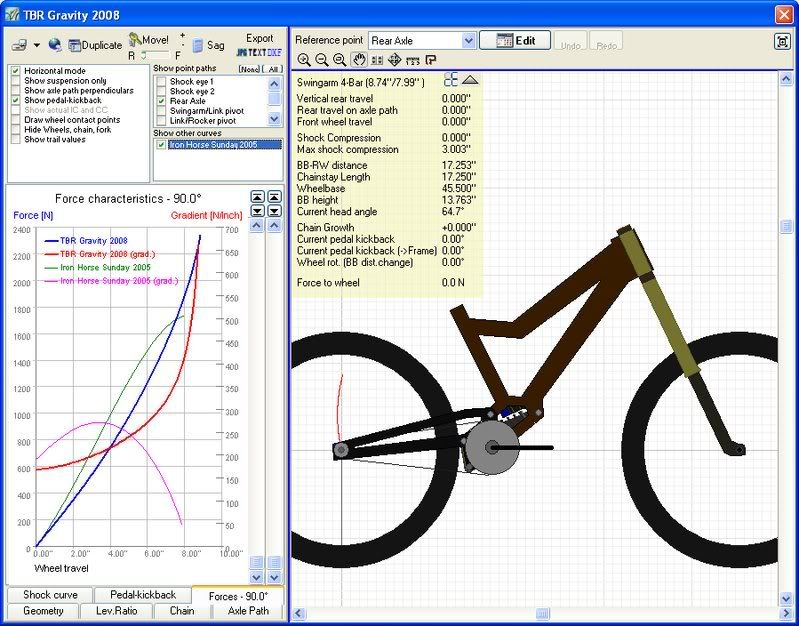

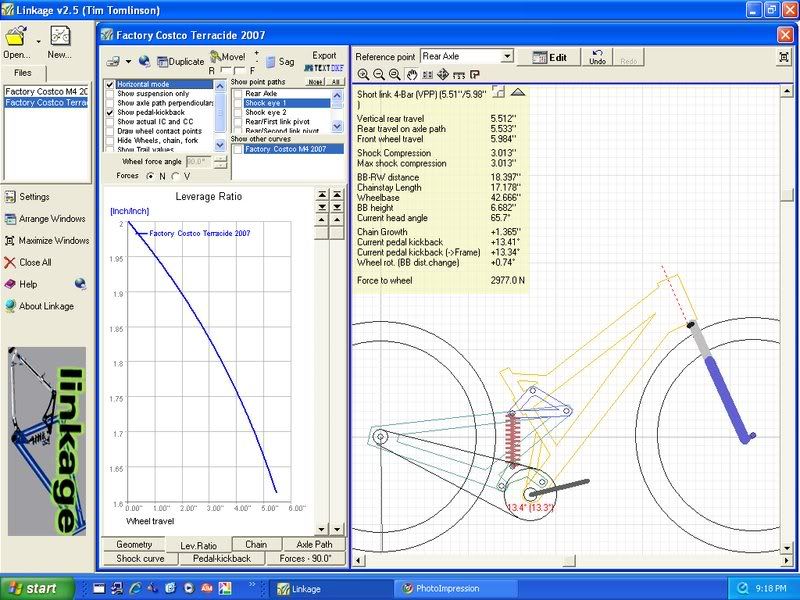

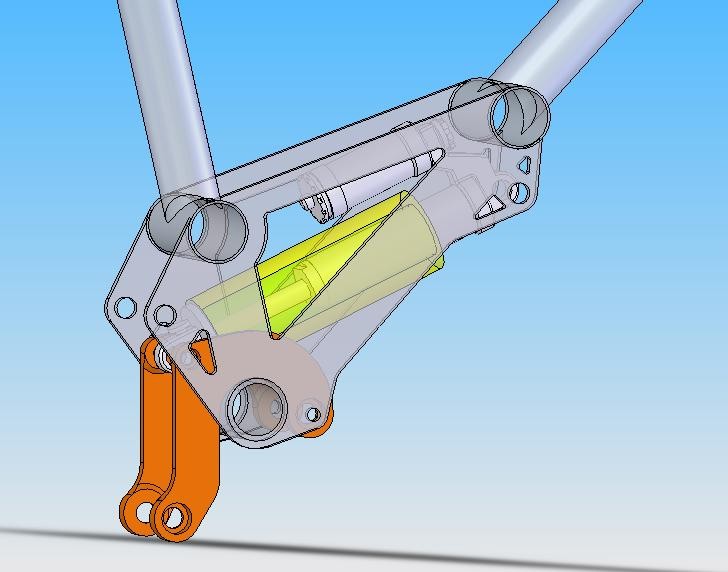

end result

I'll start it off with one of my recent designs. It's called the jesus... nobody fvcks with the jesus... nvm, bad reference haha. anyways it's called the TBR Gravity. enjoy

unsagged

sagged

bottomed

end result

It certainly looks cool tho! But won't it be unconstrained with that many degrees of freedom? Flippy floppy!

It certainly looks cool tho! But won't it be unconstrained with that many degrees of freedom? Flippy floppy!