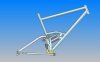

Right, I've been thinking about this bike for years. I've been modelling it for months. I've been refining it for...ever. It still needs some tweaks, but I'm almost ready to go to metal.

Here are the details:

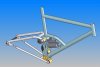

Aggressive trail bike. 6-7" travel via Fox DHX Air. 853 or similar front triangle and rear swingarm, with flexible chainstays (ala Yeti 575). Aluminum CNC'd rocker link and BB braces. High pivot design (for backward arcing rear travel - ultimate in bump absorbtion) and ADJUSTABLE chain idler pulley. Yeah, this is the first adjustable one I'm aware of - you can set it low to sprint well, or high to minimize pedal feedback. Low CG. Longish enclosed seat tube. All pivots use thru-axles for maximum stiffness in the rear end.

I won't go into geometry, as it's set up for my 6'4" frame, but consider it very similar to a Specialized Enduro - longish TT, short rear end, 67.5 HA.

Construction will hopefully happen by a very high quality builder over here in England. I had FTW look at it a while back, he'd do it (in a previous Aluminum version) for a pretty penny. I thought I'd better post my design now because I heard he's coming out with a new design - just in case it's something similar!!!

Regardless, the steel bike will use the sexiest of all joining methods...fillet brazing. Steel was used for it's compliance and fatigue resistance - steel is still real.

What does everyone think?

Here are the details:

Aggressive trail bike. 6-7" travel via Fox DHX Air. 853 or similar front triangle and rear swingarm, with flexible chainstays (ala Yeti 575). Aluminum CNC'd rocker link and BB braces. High pivot design (for backward arcing rear travel - ultimate in bump absorbtion) and ADJUSTABLE chain idler pulley. Yeah, this is the first adjustable one I'm aware of - you can set it low to sprint well, or high to minimize pedal feedback. Low CG. Longish enclosed seat tube. All pivots use thru-axles for maximum stiffness in the rear end.

I won't go into geometry, as it's set up for my 6'4" frame, but consider it very similar to a Specialized Enduro - longish TT, short rear end, 67.5 HA.

Construction will hopefully happen by a very high quality builder over here in England. I had FTW look at it a while back, he'd do it (in a previous Aluminum version) for a pretty penny. I thought I'd better post my design now because I heard he's coming out with a new design - just in case it's something similar!!!

Regardless, the steel bike will use the sexiest of all joining methods...fillet brazing. Steel was used for it's compliance and fatigue resistance - steel is still real.

What does everyone think?

Attachments

-

37 KB Views: 646

-

45 KB Views: 538

-

36 KB Views: 434

-

62.1 KB Views: 769

I was going to put a plate gusset between the seatstay and chainstay to reinforce that area and keep it from flexing at the drop out. I probably wouldn't have to TIG it that way. And I'm planning to use high carbon steel for the flexible part. The chainstay itself will be quite thin steel tubing, which will have some natural flex anyway. The amount of vertical deflection that stay will go through is about 20 mm at the free end...I thought that was too much without including a flexible piece in there.

I was going to put a plate gusset between the seatstay and chainstay to reinforce that area and keep it from flexing at the drop out. I probably wouldn't have to TIG it that way. And I'm planning to use high carbon steel for the flexible part. The chainstay itself will be quite thin steel tubing, which will have some natural flex anyway. The amount of vertical deflection that stay will go through is about 20 mm at the free end...I thought that was too much without including a flexible piece in there.