OK fellow Monkeys;

Some of you may know from other threads that I have been posting in that I am currently building my own G-boxx DH Bike. Well, I am just back from the Waterjetters and I can't shut up about it anymore! So, I am starting my own thread (a bit like Havefaith did) following the progress of the frame.

A wee bit about the frame design;

It is based around the G-boxx2 gearbox.

It has a Split-Pivot rear end.

I am testing an Anti-Squat idler system.

Rocker Link to give a slighty progressive rear wheel rate.

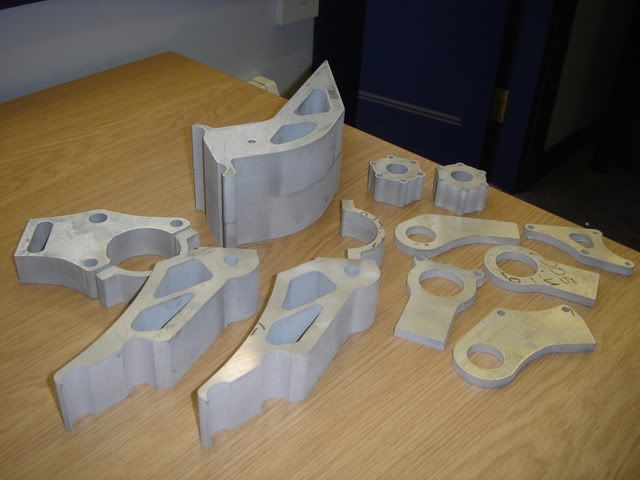

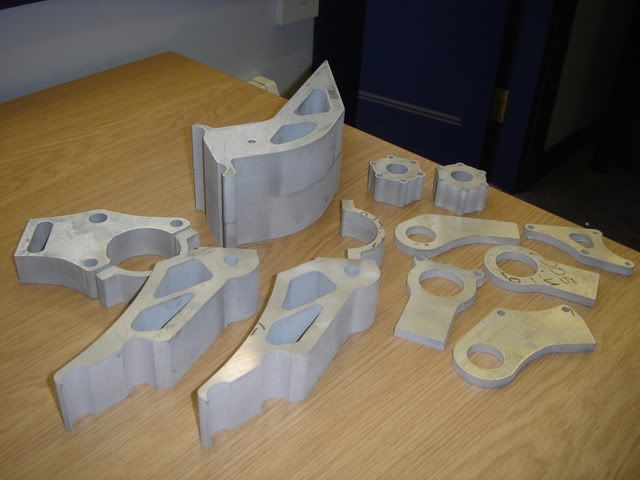

I don't want to show my CAD drawings of the frame just yet (don't want to give everything away at once!) but here are a few small pics of stuff so far(some of the waterjet stuff has still to be milled out);

What d'ya reckon?

P.S.- It won't be flexy, will not come in Rootbeer, and won't need moar shimz!

Some of you may know from other threads that I have been posting in that I am currently building my own G-boxx DH Bike. Well, I am just back from the Waterjetters and I can't shut up about it anymore! So, I am starting my own thread (a bit like Havefaith did) following the progress of the frame.

A wee bit about the frame design;

It is based around the G-boxx2 gearbox.

It has a Split-Pivot rear end.

I am testing an Anti-Squat idler system.

Rocker Link to give a slighty progressive rear wheel rate.

I don't want to show my CAD drawings of the frame just yet (don't want to give everything away at once!) but here are a few small pics of stuff so far(some of the waterjet stuff has still to be milled out);

What d'ya reckon?

P.S.- It won't be flexy, will not come in Rootbeer, and won't need moar shimz!

Last edited:

Intressting project

Intressting project ,im gonna follow this thread

,im gonna follow this thread .Can't wait how the complete bike looks like

.Can't wait how the complete bike looks like